|

Xado Frequently Asked Questions

Technical

advances have a dramatic impacts on our every day lives. Technologies

once considered something beyond imagination, are now becoming

commonplace, for instance, mobile telephones, Internet technologies,

cloning experiments, and so forth. One such technological advance is

the recent discovery of revitalization. Rather than just changing man’s

view on repair in the conventional sense of the word, it opens new

resources in operating machines and mechanisms.

At present, XADO is

making active and sweeping inroads into different areas of science,

technology and production and while technologies are emanating from

laboratories around the world for new industries, power engineering and

transport, we invite you to jointly explore how the XADO revitalizant

can dramatically change your life.

You, our potential customers, no

doubt have questions you need answering. This Frequently Asked Questions Section, FAQ for short, will

answer the most typical, and most frequently asked questions, which we

received our over the past years. Conventionally, they fall into

three categories: Vehicles, Industry and Firearms.

We will also explain the physics of the process and demonstrate it

graphically. Once you understand how XADO works, we hope you will be

excited to try XADO for yourself.

To view the Frequently Asked Questions (FAQ's) in detail click on the headings below:-

About

Xado

and revitilization

What is

Revitilization?

The term

“revitalization” (from Latin “vita”

– life) literally translated means “returning to life”. The discovery

of the revitalization phenomenon is based on unique physical and

chemical processes, which, under specific conditions, can occur in the

friction zone. In short, their essence consists of the following:

during mechanical operation, excessive loads occur in the friction

areas. At extremely heavy loads, excess destructive energy is released.

But if we introduce a unique building material – a revitalizant – into

the friction zone, then the energy released by the friction, will

actually bind new material to the friction surface instead of

destroying the material surface.

How

does it usually occur?

Let us imagine a flaw

in one of the friction

surfaces. In this case, it is a scratch (in the cross-section) made

along the axis of motion of the surfaces. Here, the metal atoms have

non-compensated double bonds, i.e. such atoms, if force is applied, can

be easily “captured”, energised to build up their oscillation, and

detached from the matrix. Imagine a tree growing on the edge of a

ravine. Due to the influences of water and wind, the soil gradually

erodes the soil to expose the roots. The tree becomes unstable, and a

strong gust of wind would be enough to uproot it. In simple terms, the

same process occurs during surface wear. Atoms are easily dislodged and

surface wear develops. Furthermore, under excessive loads, entire

groups of atoms – clusters – can become dislodged, causing extreme wear.

This has always been the case until the phenomenon of REVITALIZATION

was discovered, when scientists found that it was possible to reversing

the process of wear by restoring the worn-out surface! It turned out

that conditions could be created when the affected part is able to

restore its surface thickness and size to its initial dimensions. To

create such favourable conditions, it is necessary to introduce a

specially synthesized substance – XADO revitalizant into the friction

zone. It contains the building material for the new surface and a

unique energy activator, which enables the excess friction energy to be

harnessed in order to create a new matrix – in fact, a brand new

surface.

How

does the surface grow?

Revitalization

starts in the areas where the greatest friction (the zone of heaviest

wear) occurs, since it is exactly this location where sufficient excess

energy exists to initiate a new process, and where metal atoms have the

greatest number of free (non-compensated) bonds. These bonds, like

magnets, capture and hold the building material – the revitalizant -

where it is needed. Under the presence of the active load, the energy

activator harnesses the excess energy to construct a new matrix. In

simple terms, a new coating is formed on the old worn surface. In

several minutes after the onset of revitalization, a cermet patch will

appear on the scratch. The highlighted zone, the zone of abnormal

activity, has disappeared. The energy processes have stabilized and

surface growth stops. At the same time, mutual diffusion of two

substances (metal and cermet) takes place to complete the process of

building a new coating, cementing, and finally eliminating the flaw.

the more the process continues the stronger the new surface becomes.

How is

surface growth controlled?

Let us examine a part

under a microscope.

Even the smoothest surface, at high magnification, looks uneven and

represents a continuous series of peaks and valleys. In time, wear will

erode a weak surface and will dislodge and “expell” metal atoms,

turning them into chips and making the grooves deeper. 100 % wear

occurs, not when the part completely disintegrates, but when the

magnified peaks start to abrade. As long as these peaks exist, the part

can be restored by revitalization. However, the part will never gain in

size more than required. As soon as the valley and peak become equal,

the energy conditions required for revitalising disappears, and the

conditions stabilise. As soon as the surface starts to wear in another

location, the revitalazant left over form the previous treatment will

immediately start revitalization all over again.

How big

can the build up be?

The actual layer

created by XADO revitalizant

is measured in microns (one-hundredths of micro meter in the engine and

one-tenths of a micro meter in gear box wheels.

What

does revitilization give?

Firstly,a new coating

is formed on the

surfaces of the friction pairs increasing the size by reclaiming the

“one-hundredths” and “one-tenths” of material eroded from the surface

and that is now suspended in the lubricating oil from the previous

operations. This means ACTUAL REPAIR. Secondly, the coating created has

a new unique property, namely, it is extremely robust, highly resistant

to corrosion, with an extremely smooth surface. Therefore, after

revitalization has begun the materials life expectancy will increase by

2 to 4-fold. This means PROTECTION FROM WEAR. Due to revitalization,

you end up with a reconditioned part, which, to all intents and

purposes, is superior to a the original.

You

claim that the coatings obtained are unique. What are the key features?

The key features of the

part’s surface before

and after revitalization are as follows: increase in micro hardness

(kg/micro metre2) from 65-280 to 650-750 range, after treatment; the

roughness coefficient (Ra) before revitalization was 0.9-2.1, and after

treatment it is 0.06; and above all a dramatic increase in

corrosion-resistance characteristics.

Has XADO

been tested?

Has

XADO been tested by a world recognised

testing authority?

Yes TÜV Thüringen,

Germany one of the worlds

leading inspection agencies has tested XADO. TÜV approval and the

certification procedures are without question one of the most strictest

and comprehensive testing procedures in the world and involves rigorous

testing and verification that the product satisfies the strictest

European regulations for the industry in which the product was designed.

TÜV unequivocally confirms effectiveness of Xado and that Xado reduces

fuel consumption, increases compression and reduces exhaust emissions.

What

equipment was used by TÜV to verify their

results?

The TÜV specialists

used industry standard equipment

to measure compression, toxicity of exhausts, as well as chassis

dynamometer to measure engine power, etc. You can see additional

examples of tests on customer vehicles on our testimonial page.

Why has

XADO not been tested using ASTM Falex

equipment?

The ASTM Falex test is

the Standard Test Methods for

Measurement of Extreme Pressure Properties of Fluid Lubricants (i.e

using the Falex Pin and Vee Block Methods). As Xado is not a lubricant

it can’t be tested with this system.

What

other tests gave been carried out?

Apart form TÜV

customers and clients have carried out

their own test. You can see some of these on our own web site as well

as forums accross the internet.

How Xado

can help Vehicles, Cars, Trucks and Buses

I have

a new Vehicle. Why do I need XADO?

During the first few miles

when a new vehicle

is being run-in, adjustment of friction surfaces takes place.

Revitalization allows the vehicle to be run-in with the minimal of

material wear, and offers the unique chance of preserving the entire

machinery. The surface does not wear out because it is protected with a

cermet coating, which is more durable than metal surface matrix. It

will be the new cermet protective layer that will be subject to wear

and tear, not the original metal surface. Note that during

revitalization, the friction surfaces adjust to one another

individually, this is only possible during manual assembly. This means

you will receive a custom fitted engine in your vehicle!

If you

are about to embark on a major engine overhaul, you’re just in time!

Revitalising is critical

for engines that

have been overhauled because during typical overhaul you cannot repeat

the steps the original surface hardening. When boring an engine, the

upper layer that is especially hardened is removed. And, if prior to

first boring, the engine was running for about 200,000 km on average,

then after the major overhaul this figure will fall to 70,000 km. This

would ultimately happen if you do not use our XADO treatment. XADO will

harden the surface for you!

If the

engine is new, or has just completed a major overhaul, will half a dose

do?

According

to application instructions, new engines and those that have completed

a major overhaul can be treated in one step – 2 tubes at a time. So,

can my vehicle be completely restored? Nothing in the world is

infinite, and vehicles are no exception. The main point is to

understand the revitalizant operating principle, and to apply it

correctly. You see, many people suffer for years listening to the

heart-breaking grating noise coming from their gearbox, or reducer, and

are simply unaware of the fact that these failures can be easily

treated. The noise disappears in several hours after the introduction

of revitalization. Of course, there are no miracles in this world: a

broken shaft can never be repaired, but laying down a protective

coating of 0.02 to 0.05 micro metre on the cylinder wall, or of 1 micro

metre on gears, is easily achievable.

How

often will the engine need to be treated?

The treatment again depends

upon the amount

of oil in the engine-and-gearbox unit (see question above). If you have

used any of the engine treatments, which includes the three stage

blister packs, the advanced 1 stage products or the 1 stage metal

conditioners This varies from 1 blister pack treatment up to 9 blister

packs for larger engines. The treatment for an average petrol or diesel

saloon car with an oil capacity of 3 to 10 litres, is 3 blister packs.

Don't worry this is NOT required immediately but, these will last for

100,000 Kilometres (65,000 miles). We are one of the only product that

will last so long, unlike other products that require you to repeat the

process every 20,000 miles!

There

is nothing wrong with my Car, but would

XADO still help?

XADO would certainly help; not

least it will

protect your engine against any future problems. Even if you

think there is no existing problem with your engine, there will always

be minor areas or wear that XADO will restore. View XADO as an

insurance policy.

What

impacts does XADO have on the oil retaining cylinder bore crosshatch

finish?

It is widely agreed that

the crosshatch

finish on a cylinder wall is vital to help retain oil on the cylinder

wall surface.

The application of XADO has

no effect on the

lubrication of the cylinder surface as the cermet coating is olephelic,

(oh-lee-oh-fil-ik),

meaning the coating attracts oil. The olephelic nature of the

cermet coating not only retains oil, but also significantly reduces

friction between the piston rings and the cylinder walls.

In fact by using XADO you

will help to refine

the bore Geometry?

Will

the cermet layer grow and cause engine seizure?

No, the engine will not

seize. Revitalizing

is self-regulating. In fact, the formation of a cermet layer takes

place in both friction surfaces that are affected by the same load. due

to the high pressure and temperature, a cermet layer starts to form

between the friction surfaces. Its thickness increases pro rata to the

wear (the process was explained in the answer to question 1). As soon

as the original worn surface has been repaired, the friction factor

drops dramatically, and the XADO activation energy will also decrease.

The process then stabilizes, and at some point, the energy will drop to

a point where cermet growth will stop completely.

Does

XADO pass through the Oil filter?

The gel when added to the

oil completely

breaks down It passes through the filter with the oil.

Will

XADO affect the Turbo or Catalytic converter?

No, XADO will not affect

the turbo or

catalytic converter. It will not harm them in any way.

Can the

XADO composition, mixed with the engine oil, settle on the bottom of

the sump during prolonged parking of the vehicle and, as a result, lose

its effectiveness?

According

to application instructions, after the revitalizant has been

introduced, the engine has to be run at idle for at least five minutes.

This is enough time for the revitalizant to locate the areas of

friction and begin it's work and will not be affected by periods of in

activity, such as parking.

When my

car is idling, the oil pressure lamp blinks. Will XADO help?

There are many causes of reduced

oil pressure,

ranging from trivial failure of the oil sensor to a worn out oil pump,

bushings, or crankshaft journals. If the wear is not catastrophic (not

100 %), XADO will definitely help! In any case, consult a certified

technician.

Will

XADO help with my excessive oil consumption?

The causes of excess oil

consumption are

numerous. Some of them are easy to eliminate, while others present a

serious problem. If the problem is due to the extreme wear of the

sleeve assembly, XADO can help, but even here, the degree of wear is a

key factor. Let us remind you of manufacturers’ recommendations:

consumption of 1 litre of oil per 1,000 km (for a petrol engine) points

to practically 100 % wear, so a good mechanical diagnostics is always

necessary.

How do

you prove the claim of fuel saving up to 30%?

As a rule, excessive fuel

consumption is

caused by worn sleeve assemblies. After revitalization, the assembly

geometry will be restored, and fuel consumption will be restored to its

original value. In addition, a lower friction factor (surface finish

0.06 Ra instead of the usual 0.9 to 2.1 Ra) will significantly reduces

friction loss. The result is a dramatic increase in fuel savings, up to

30 % at idle and 5 to 7 % when driving.

Why

does compression in cylinders increase?

By restoring the cylinders’

geometry,

compression grows by 10 to 20 % as early as in the first 500 to 1,000

km of operation. We have witnessed cases when the compression increased

from 4 - 6 atmospheres to 10 - 12 atmospheres. Usually, low compression

values are caused by mechanical damage (piston burnout, valves, etc.),

rather than by natural wear.

I have

scheduled two major overhauls. Can the engine be re-bored as usual, or

will I run into a problem cutting through cermet layer?

Of course, to be on the

safe side the engine

should be re-bored! Keep in mind that the cermet layer is formed to a

depth of 10 to 30 micro metre, whereas the cutter removes a much

greater layer of metal. But do you really need conventional major

overhaul? The exceptional capacity that enables XADO technology to

restore the geometry of engine parts will allow you to avoid these

labour-intensive and expensive repairs. For instance, the repair of the

sleeve assembly can be reduced to replacing damaged piston rings or

replacing rings that have completely lost elasticity, replacing a

burnt-out piston, etc. In other words, you would only need a

“face-lift” repair, which takes only a few hours.

Will

XADO stop my engine smoking?

Yes but it depends on

the colour of the smoke coming

from your exhaust.

White smoke is caused by water and or antifreeze entering the cylinder,

and the engine trying to burn it with the fuel. In this case you need a

new cylinder head gasket and XADO cannot repair this.

Black smoke is caused by excess fuel that has entered the cylinder area

and cannot be burned completely due to faulty carburettor, fuel pump,

or a leaky fuel injector. XADO will certainly help the faulty

fuel pump, particulary if you have a HPFP, in which case you can use

our XADO gel for HPFP.

Blue smoke is caused by engine oil entering the cylinder area and being

burned along with the fuel air mixture. The car has many seals,

gaskets, O-rings and piston rings that are designed to keep the engine

oil from entering the cylinder. XADO cannot treat the gaskets and

O rings but is can treat the piston rings.

I own

an old car and the engine sounds a little noisy?

Try using XADO engine

blister pack or the

single 1 Stage Advanced engine treatment, which comes, in a tube or as

a metal conditioner.

My

vehicle has just failed it's MOT due to high exhaust emissions, will

XADO help?

Try one of our engine

revitalizants. We have

had many customers used our products to pass an MOT. Of course it

depends on state of your engine, but there is no harm in trying.

I'm

interested in improving the compression in my engine. Will one blister

pack of the 3 part treatment be sufficient to improve compression?

One blister pack will

certainly help but it

will not complete the process of full revitalization. There is no harm

in trying and you can always order additional blister packs as and when

you want to.

Can

XADO be used in old classic Cars?

Yes, XADO can be used with

any vehicle no

matter its age. We have many classic car owners who use XADO.

Can

XADO be used in engines with wet clutches, Audi tiptronic gearboxes and

rotary engines?

Yes, XADO will work in all

engines. If the

engine is in reasonable condition, but in need of some revitalization

the product will work. If the engine is excessively worn it will still

work but the results will be less noticeable, and would be best

accompanied by any necessary mechanical repairs.

I have

noticed a slight whine from the differential. Will XADO help?

Yes XADO will help.

We have our

revitalizant designed to treat gearboxes and differentials.

Will

XADO work on a Nikisil coated engine?

Yes XADO will work on a Nikisil

coated engine, and

no it will not strip the bore lining of it’s original Nikisil

coating? We have experienced with this coating as well as other

similar coatings and XADO works well.

Can I

use XADO in an engine with a dry sump?

Yes XADO can be used in any

engine whether it

has a dry or wet sump.

Will

XADO quieten engine tappets?

Noisy tappets can be due to

inaccurate tappet

adjustment so this may need to be adjusted manually. If there is

some wear and tear on the metal surface then XADO will help.

Again, try it and see if it helps, it will do not harm.

Can

valve guide rods be reconditioned?

Valves

are protected with special oil-scraper cups (valve seals), so the

amount of oil getting onto the valves and, respectively, of

revitalizant, is small. If the valve wear is insignificant, the small

amount of revitalizant is sufficient to protect and preserve the

valves. If the wear is heavy, it will be necessary to replace the

valves and the guide sleeves.

When

treating ICEs, should the cylinders be treated also?

No,

that’s not required. It’s quite a different matter if you want to

restore the compression in one, two, three, or more cylinders without

treating the entire engine, or to eliminate ring sticking (this is a

frequently occurring problem because any overheating of the engine

contributes to ring sticking). In this case, the gel revitalizant for

reconditioning cylinders is exactly what you need!

My

Vehicle is very noisy in 5th gear. I changed the oil, but that didn’t

help. Will XADO help?

A

gearbox that is noisy in it's highest gear is not uncommon even in some

new vehicles, in which, due to design features, the fifth gear runs in

a almost lubrication dry state. Earlier, attempts were made to solve

this problem by adjustments. However, no adjustments are capable of

coping with the wear that has already occurred and preventing future

wear. The addition of the XADO gel revitalizant allows you to eliminate

for good the noise that occurs in five-speed CSGs, as well as to

improve positive gear change. The repair will appear within 25 to 30

miles after treatment.

If

one takes your ads seriously, then it’s possible to run with no

lubricant at all?

We

ran an engine with a dry case only to demonstrate the quality of the

CERMET coating. The first dry run was undertaken in early 1999. A

renowned racing driver drove a vehicle at maximum speed, and performed

complex driving maneuvers in a car without a drop of lubricant. He

became a believer in XADO only when he had “burned” a set of tyres.

Driving without any lubricant was an obligatory requirement to obtain

the Chinese state certification. The Chinese diesel-engine truck

“Liberation” with an 8-ton load was driven with a dry case during a

complete day work shift for 204 km! The truck is now back in

operation, and is checked regularly. All the improved parameters,

obtained during treatment, remained intact!

It wasn’t XADO’s intention to manufacture a product for “dry driving”.

Why do we set up such demonstrations? And why do we write about them?

The answer is straightforward: We demonstrate that it is possible to

drive with a dry oil case only to show the quality of the CERMET

coating created by the revitalazant, and for you to understand that, by

treating your car, you will be provided with not only a revitaized

repair, but a guarantee against extreme oil loss! Now your

vehicle is protected by XADO, and XADO won’t let you down!

I use

Hydrogen as a fuel and I am concerned about hydrogen embrittlement.

Will XADO help to protect the engine?

Indeed, XADO can

prevent hydrogen

embrittlement. As

XADO creates a CERMET (ceramic/metal) layer on any friction surface it

encounters which creates a barrier against the absorbsion of hydrogen

by the underlying metal structure thereby preventing embrittlement.

How

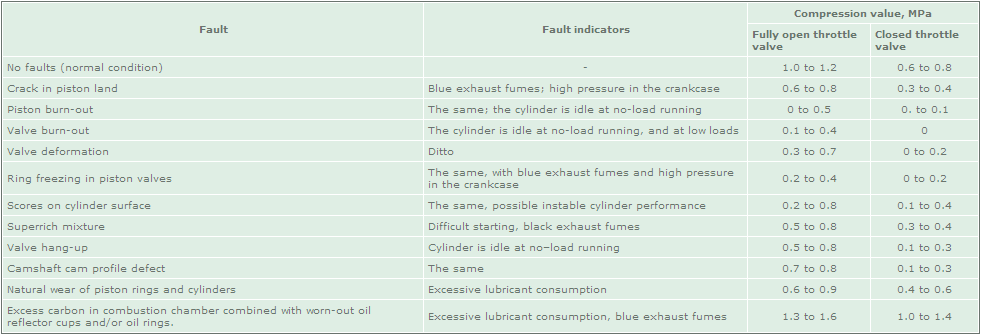

can the engine compression be measured properly?

Here is an advice from

a renowned expert, the

Director of the firm “AB-Engineering”, A. Khruliev, Ph.D.:

When measuring the compression, observe the following rules: warm up

the engine, and cut off the fuel feed. To do so, you can switch off the

fuel pump, close the nozzles, or use any other methods preventing the

feed of fuel into the cylinders. Remove all the spark plugs. Selective

removal of spark plugs, practiced by some service centers, is

inadmissible since this increases the rotation resistance and

spontaneously reduces the revolutions when the engine is cranked with

the starter. The storage battery should be fully charged and the

starter should be in good condition. The compression is measured with

both an open and a closed throttle valve. Both methods yield respective

results, making it possible to define specific defects (see the Table

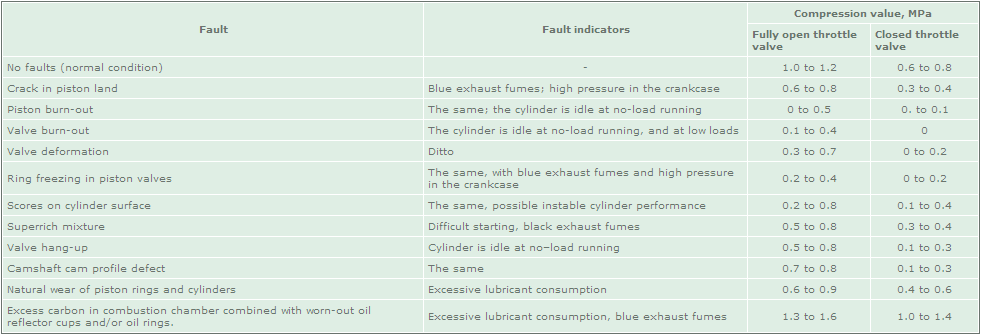

below).

Defects and faults in a petrol engine detected by measuring the

compression.

Motor

Cycles & Scooters

Compatibility

with other products and questions

about XADO's make up

Is XADO

compatible with other additives on the market?

Of course, you can. The

XADO technology is

compatible with all additives, metal conditioners, and re-metalisants,

no matter how often they were used.

Does

XADO contain any PTFE, Boron, Moly, Zinc, Chlorinated Hydrocarbon etc?

No, XADO does not contain

any of these

products. These products can damage your engine and in certain

circumstances are toxic and carcinogenic. XADO is very safe to use.

Is XADO

an Extreme Pressure Additive (EPA)?

No XADO is not an EPA as

EPA’s traditionally

contain sulfur or chlorine compounds which can react with water and

combustion by products, forming acids that facilitate corrosion of the

engine parts and bearings. As you have seen form our website XADO

causes none of these.

Which

product should I use and how to apply it?

What is

the difference between the gels and aerosols?

The gel revitalazant in

tubes are our

original products and though easy to use, it can be difficult to use on

some engines, gearboxes etc, where the oil filler neck or plug is in a

difficult to reach location, so we designed the aerosol. This comes

with a convenient tube, which you attach to the aerosol nozzle allowing

you to reach these in accessible places.

What is

the difference between the traditional 3 stage gel blister packs, the

Advanced 1 Stage treatment?

The

traditional gels in the blister packs are part of a three stage

treatment. These are applied every 65 miles and after the third

tube is used your treatment is complete. Some customers did not

want the trouble of a three stage application, so we designed the new

advanced 1 Stage treatment. As the name implies you only have to

apply this once and you treatment is complete. (The amount of XADO

required depends on you engine or gearbox oil capacity. Please

refer to the appropriate product dosage.)

The new advanced 1 stage revitalizant can be used with all types of

engines petrol, diesel, and LPG, whereas the traditional gel products

are specific to the particular type of engine. (i.e. petrol gel

revitalizant for petrol engines only).

Why

should I use the metal conditioners rather than the gel revitalizants

described above?

The metal conditioners

contain exactly the

same revitalizants that is in all our products, except they have two

additional enhancements. The first is what we call a 2D sliding agent,

which provides additional anti friction properties. The second helps to

enhance the lubricating properties of your oil by strengthen the oils

lubricating capacity.

Will I

damage my engine if I use too much XADO?

No, XADO will not damage

your engine. XADO

revitalizant in gel aerosol or granular form are completely soluble in

the oil and do not change the viscosity of the properties of the oil in

any way. Remember XADO is self-regulating. As soon as the original worn

surface has been repaired, the friction factor drops dramatically, and

the XADO activation energy will also decrease. The process then

stabilizes, and at some point, the energy will drop to a point where

cermet growth will stop completely. Besides, using too much is just a

waste of money.

Do I

need to flush my engine before using XADO?

No, you do not need to

flush your engine as

part of the revitization process XADO cleans the metallic surfaces.

However if you do feel your engine needs flushing, try our Vitaflush

product, which will not only flush the engine but will also restore it.

I

bought some gel revitalizant blister packs but find I cannot squeeze

the gel into the oil filler neck. What should I do?

Mix the contents of the

tube with a small

amount of oil warmed up to room temperature. You can then pour this don

the oil filler neck.

I am

just about to change the oil in my vehicle. Should I use XADO before or

after the treatment?

You can

use XADO in either

case, but for the full treatment to take place you must not change the

oil until 1,500 km after using the treatment. For some of

our treatments this may be less depending on the product you are using.

I am in

the Motor Tade, how can XADO help me?

Indistrial

Manufacturing and Equipment

How are

grease lubricated mechanisms revitalized?

This

is possible by using our XADO greases. First, determine the degree of

wear, and depending on this, use the appropriate XADO grease.

Protective Grease is used for new assemblies, or those with

insignificant wear (up to 10 %); it is a versatile substitute for any

grease. Restoring Grease contains a greater number of active

components, so, rather than just protecting the part’s surface, it also

restores its geometry. It is used for assemblies and mechanisms with a

degree of wear up to 50 %. Repairing Grease is used for assemblies with

80 % worn surfaces.

How do

I apply the XADO Grease to a bearing?

Here the rules are the same

as for any other

lubricant. First, remove the old standard grease, and then apply the

new grease. Do not completely fill the inner bearing body with grease -

this is a common error. Excess grease in a bearing is, in fact,

provides an additional load which cause overheating and will accelerate

wear. Refer to manufacturer’s suggested amount of grease that can be

applied. XADO grease can be used for the entire service period of the

bearing (or other assembly), and requires no subsequent replacing.

Can

roller bearings be reconditioned separately from the mechanism which

they are part of?

In principle, this is

possible, but when

revitalizing a bearing assembly in the standard way, the acting

surfaces are adjusted independently to one another. However, if

revitalization is performed on a bench (let’s call this method an

artificial one), then after the bearing has been refitted, it may be

that the bearing will not run with the reconditioned friction surfaces.

Our

company uses machine tools. How will we benefit from this treatment?

A machine tool is a complex

piece of

equipment, but it is still a mechanism, so naturally, revitalization

improves its performance. We would like to draw your attention to the

extreme effectiveness of XADO for high-precision machine tools. The

spindle is the key component of any machine tool. It is a highly loaded

assembly running at high speeds (up to 30,000 rpm, and in coordinate

grinding machines the speed even reaches 84,000 rpm). This leads to

significant wear in a very short time period. Experts know that

conventional repair of such assemblies is, in many cases, impossible

because of the specificity, complexity and shortage of parts. Here is

where XADO comes handy! Revitalization with one of the special

high-speed XADO greases allows the spindle operations to achieve the

required certification. Rejects are practically eliminated, this being

of critical importance during any finishing operations.

Railways,

Aircraft, Energy and Marine Industry

Fire

Arms and Artillery equipment

You

claim that XADO will treat any firearm barrels large or small?

Yes, XADO technology will

recondition any

mechanisms, simple, complex, small and big, ranging from watches to

nuclear power plant turbines – wherever where there is motion and

friction. For a clear, effective and fast demonstration of the

effectiveness of the technology, there is no better example than a

“projectile & barrel”. Here is an ideal example where all the

conditions required for the formation of the CERMET coating are in

place, namely a very high temperature, significant friction energy and

interaction of materials with different strengths. The revitalization

process takes place literally in front of your eyes. The Russian

certified handgun test laboratory “Rzhevka” military unit 33491, in

association with “Kalashnikov. Firearms. Ammunition and Equipment

Magazine” carried out extensive tests. The tested included both new and

used firearms with chromed and non-chromed barrels.

What

does XADO barrel treatment provide?

Revitalising a rifle barrel

provides the

following: geometry restoration (complete shuttering) and protection

from the wear of the bore surface; maximum impact force for the given

type of ammunition; a 10-fold increase in wear resistance and barrel

life; an increase in firing flatness, the key factor is a 2 to 3 fold

increase in firing accuracy!

Is any

preliminary preparation of the barrel needed prior to revitalization?

No special preparation is

needed. Standard

cleaning of the bore is enough.

What

is the point at which XADO will stop revitilizing a worn barrel?

The XADO revitalizant

improves the firing

performance of any firearm however worn.

What

is the service life of a reconditioned barrel?

A special experiment was

needed to answer

this question. First, a new chrome barrel was revitalized. Even though

the barrel spread characteristics, complied with the standard

acceptable, the firing accuracy increased by 23 % after treatment with

XADO!

Next, the durability tests were

conducted. This

meant firing 200 tracer rounds in succession. The firearm became so

sizzling hot that the stock varnish coating began to run. It was cooled

in the simplest way by dipping it into a bucket of water. Everybody

waited impatiently for the results of the test. Sceptics wagered that

the coating wouldn’t withstand the extreme temperature drops and would

simply peel off. The results surprised even the developers of XADO! The

firing accuracy increased by an additional 46.6 %! The service

life tests carried out at the Rzhevsk test facility allow us to claim

that the service life is 10,000 shots with no loss of improved

performance. Under normal loads, you’ll be able to keep the barrel in

an ideal condition at all times by treating it once a year with the

appropriate XADO treatment.

Does

the treated barrel need any maintenance?

No special maintenance is

required. Moreover,

the protected inner surface of the barrel is subject less to corrosion

attack than conventional coatings are. Remember that chippings and

micro cracks are restored even on chromed barrel coatings!

In one

case, the firearm with a reconditioned barrel was kept in a room with

high humidity for several months. Will the revitalizing effect

disappear?

No, it won’t. Special

barrel rusting and

exposure tests have shown that the performance of a treated barrel does

not degrade.

Does

it make any difference whether the barrel is chromed, or not?

The revitalizant improves

the accuracy of any

barrel, both chromed, and un chromed.

I am a

marksman, and own a top of the range rifle. How will I benefit from

revitalizing the barrel?

After revitalization,

shooting accuracy, even

for high-precision barrels, will certainly increase.

I have a shotgun

with a pitted chrome barrel. Will XADO help?

Yes, it will. The main

point is to observe

the revitalization principle, i.e. to ensure sufficient friction by

contact between the bullet and barrel surface. You might want to use a

bullet of a special design. In which case, you can draw more extensive

conclusions and back up both of our tests.

Other

general questions you may ask about Xado?

I have

been told that I should not use an additive in my oil?

All engine oils and greases

have some form of

additives added by the manufacturer. In fact without these additives

the oils and greases would not do their jobs properly, so it is a

fallacy that there are no additives in any of oils and grease and that

you should not use additives to further enhance your engines

performance, purely on the basis that the oil companies do not use them

– they do.

You must remember XADO is

different as it is

NOT an additive. The oil or grease is used as a carrier to deliver XADO

to where it is needed.

There

are several of products on the market that seem similar to XADO. Are

they the same?

No they are not the same

and some of them can

damage your engine. XADO is the original and all others are attempting

to copy our process.

Why is

XADO not stocked by the major UK retail chains?

The reason why we are not

on the high street

is purely the fact that the major retailers do not always do justice to

a popular product. We feel as though we can do better. We in fact

regularly achieve the top position in most search engines so much of

our sales are based online and we ship direct to individuals, dealers,

motor factors and garages. Many of our customers order form us by way

of a recommendation.

Do I

have to order the product online or can I place an order by calling

your office?

We are happy to deal with

your order in any

way you wish. If you are happier calling our office within office hours

our sales staff will gladly process your order over the phone.

Where

can I buy your engine oils?

We are currently only

offering engines oil

purchased in a minimum of 1000 gal quantities for trade purposes. Our

specialist field is in revitalization rather than lubricants as oil is

a flammable liquid distribution in small quantities is a problem.

If you are looking to gain the benefits of revitlization for your

vehicles, you are better off using one of our gel blister packs or 1

Stage revitalizants and adding this you your existing oil. If you are

also looking to change your oil then use an oil available from any

motor parts supplier and add our revitalazant to treat your vehicle.

Despite

all your information I still remain sceptical, as there have been so

many claims for "wonder" products in the past?

We can quite understand

your scepticism and

we do not claim that XADO is a one stop fix all product. XADO has been

independently tested and used by may customers in many countries around

the world. All we can suggest is to try one of our products and see if

it helps.

Is

XADO toxic?

No. All our products have a

Material Safety

Certificate (MSC). As XADO has been used to revitialize machinery

in a food processing plant XADO also has a food hygien certificate.

|

|